Pre-stretched films

The pre-stretched film has the following customer values:

Less- specific packaging cost (up to 30-50% !!!);

- order frequency;

- storage space requirements;

- inventory cost;

- product charge (spools, cardboard, foil)

- waste;

- human exercise.

Pre-stretched films |

|||||

| Type | Width (mm) | Thickness (my) | Color | Length / roll (meter) | Quantity / pallet (roll) |

| Hand pre-streched film with core | 430 ; 390 | 5-10 | natural, black, white, blue | 300-1000 | 240; 292 |

| Pre-stretched film coreless | 430 ; 390 | 5-10 | natural, black, white, blue | 300-1000 | 136 |

| Machine pre-stretched film | 430 ; 390 | 5-10 | natural, black, white, blue | 2500-5000 | 45 |

Western Europe and many countries around the world have recognized the effects of soft plastic packaging packaging much sooner than Hungary has taken steps to reduce the use of LLDPE stretch films.

The pre-stretched film has been on the market in Europe since 2002 and was first manufactured in Hungary by Roll-Pack Kft. In 2005, we started preparations for product development and formulation of formulas. By 2007, we were able to produce a well-developed product.

Thanks to the manufacturing technology developed in packaging technology and film production, many of the properties of pre-stretched stretch film are better, significantly more economical than conventional stretch film, and due to the manufacturing technology, they are more resistant to physical and mechanical stress. The edges of the foil are folded back for a stronger hold and for a higher tensile strength so there is no foil damage or loss due to user error!

The pre-stretched films are manufactured by hand and machine. Handmade transparencies are produced in two different ways, in a lightweight spool or non-spool version. These films can also be produced in color (black, white, blue, red), which can be used for marking, covering or protecting.

HandThe pre-stretched spoolless hand foil is practically usable in the so-called. plastic applicator, which is extremely quick and easy to assemble, which reduces winding time and hand injuries.

Unlike conventional hand stretch film, pre-stretched film can reduce unit packing time by 10-20%, and even provide the same stability with up to 50% less foil usage, resulting in up to 50% waste on unpacked pallets to partner less than traditional film.

MechanicalIt is recommended for users who do not have pre-loading equipment on the packaging machine but who wish to pack pallets in an environmentally conscious and efficient manner. On wrapping machines, roll replacement is reduced to one-third, as with conventional films, the pre-stretched machine foil is at least 2750 and maximum at 3500 meters per roll, as opposed to 1400-1800 meters per roll. It is characterized by reliable, stable stacking, with very significant cost savings.

Help for easy interpretation:

a, manual use, with core and coreless:

- Width: 390-430 mm

- Thickness: 5 my-10 my

- Length: 300-1000 m

- Light core or coreless solution.

- The coreless version is manufactured with an inside diameter of 76mm.

b, machine use:

- Width: 390-430 mm

- Thickness: 5-10 my

- Length: 2500-5000 m

Super Power Films: For manual and machine use

- Recommended for automatic or semiautomatic machines with a feed unit

- Exceptional puncture resistance

- Elongation up to 300%

- 20-40% saving on packaging material

- 15-30% reduction in packaging cost

Super power films |

|||||

| Type | Width (mm) | Thickness (my) | Roll weight (kg) | Elongation | Quantity / pallet (roll) |

| Machine films | 125; 250; 500 | 12-30 | 14-18 | 200-300% | 30; 45 |

| Hand films | 500 | 12-30 | 1-5 | 200-300% | 240; 288; 360 |

Available on request 600; 750 and 1000 mm wide machine stretch film. |

|||||

Thanks to their material and technology, they are made in 5, 7 layers, which make them more resistant to puncture and protruding corners, so the amount of foil waste formed during packaging is negligible. Highly recommended for heavy duty packaging machines that can unload up to 50-60 pallets per hour.

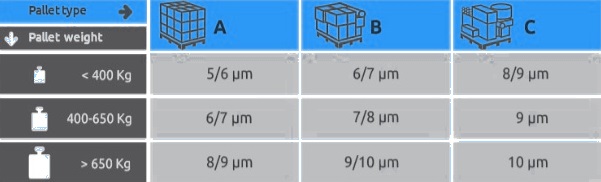

Help for easy interpretation:

a, Manual use:

- Up to 20-40% specific savings

- Increased pallet stability

- Width: 500 mm

- Thickness: 10 my - 23 my

- On a lightweight core

- Available core sizes: 0,2 ; 0,3 ; 0,8 kg

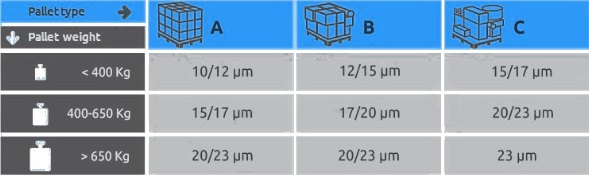

b, Machine use:

- Up to 20-40% specific savings

- Increased pallet stability

- Width: 125; 250; 500mm

- Thickness: 12 my - 30 my

Standard Stretch Films: For manual and machine use

- recommended for automatic or semi-automatic machines without pre-stretch unit

- extensibility up to 150%

- transparent in black, white and blue

Standard stretch films |

|||||

| Type | Width (mm) | Thickness (my) | Roll weight (kg) | Elongation | Quantity / pallet (roll) |

| Machine stretch films | 125; 250; 500 | 12-30 | 14-18 | 150% | 30; 45 |

| Hand stretch films | 500 | 12-30 | 1-5 | 150% | 240; 288; 360 |

Available on request 600; 750 and 1000 mm wide machine stretch film. |

|||||

3-layer film, recommended for classic, simple packaging where there is no particular requirement for packed pallets.

a, Manual use:

- Available in packs of 1 kg - 3 kg

- Width: 500 mm

- Thickness: 12 my - 30 my

- on a lightweight core

- Available core sizes: 0,2 ; 0,3 ; 0,8 kg

b, Machine use:

- Available 14 - 18 kg / roll

- Width: 125, 250, 500 mm

- Thickness: 12 my - 30 my

Kereskedőház Kft.

Office / Site: 6230, Soltvadkert, Szentháromság u. 100.

Headquarters: 2040, Budaörs, Ébner György köz 4.

Tax number: 26112493-2-13

Registration number: 13 09 188881

E-mail: info@rollpack.hu

Phone: +36/78-480-238